Introduction

Diesel generators have been a critical component of power generation systems for decades, providing reliable backup power in a wide range of applications. When it comes to powering resistive loads, diesel generators offer a robust and efficient solution. In this article, we will explore the key considerations and best practices for maximizing the efficiency and reliability of diesel generators when used to power resistive loads.

Understanding Resistive Loads

Resistive loads are devices or systems that convert electrical energy into heat or light through the resistance of their components. Examples of resistive loads include electric heaters, incandescent light bulbs, and heating elements in appliances. These loads are characterized by a constant power draw that remains relatively stable over time, making them well-suited for diesel generator applications.

Benefits of Diesel Generators for Resistive Loads

Diesel generators are known for their reliability, durability, and efficiency, making them an ideal choice for powering resistive loads. Some of the key benefits of using diesel generators for resistive loads include:

1. Robust Performance: Diesel generators are designed to provide continuous power output for extended periods, making them well-suited for resistive loads that require a constant power supply.

2. Fuel Efficiency: Diesel engines are known for their fuel efficiency, allowing diesel generators to deliver power to resistive loads at a lower cost compared to other types of generators.

3. Durability: Diesel generators are built to withstand harsh operating conditions, making them a reliable and long-lasting power generation solution for resistive loads.

4. Easy Maintenance: Diesel generators are relatively easy to maintain and service, reducing downtime and ensuring consistent power supply to resistive loads.

Key Considerations for Using Diesel Generators with Resistive Loads

While diesel generators offer several advantages for powering resistive loads, there are key factors to consider to ensure optimal performance and efficiency:

1. Sizing the Generator: Properly sizing the diesel generator is crucial to ensure it can meet the power demands of the resistive loads without being under- or oversized. Calculating the total power requirements of the resistive loads and accounting for any starting surges will help determine the appropriate generator size.

2. Load Balancing: Distributing the resistive loads evenly across the generator's capacity helps maintain a balanced power supply and prevents overloading of individual circuits. Monitoring the load distribution and adjusting as needed can optimize the generator's performance.

3. Voltage Regulation: Maintaining stable voltage output is essential for powering resistive loads efficiently and preventing damage to sensitive equipment. 500kw diesel generator for mining operations should be equipped with voltage regulation mechanisms to ensure consistent power delivery.

4. Fuel Quality: Using high-quality fuel and ensuring proper fuel filtration are essential for the reliable operation of diesel generators. Contaminated or low-quality fuel can lead to engine issues and reduced efficiency.

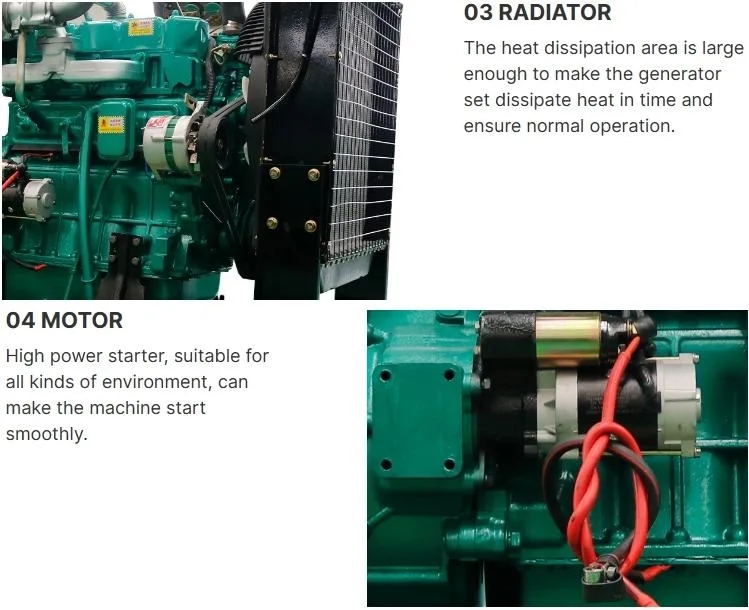

5. Cooling System: Diesel generators generate heat during operation, and proper cooling is necessary to prevent overheating and ensure optimal performance. Regular maintenance of the cooling system, including monitoring coolant levels and temperature, is essential.

Best Practices for Optimizing Diesel Generator Performance

To maximize the efficiency and reliability of diesel generators for resistive loads, following these best practices is recommended:

1. Regular Maintenance: Implementing a routine maintenance schedule for the diesel generator, including oil changes, filter replacements, and inspections, helps prevent breakdowns and ensures consistent performance.

2. Monitoring and Remote Control: Utilizing monitoring systems and remote control capabilities allows for real-time tracking of the generator's performance and enables remote operation and diagnostics, improving efficiency and response times in case of issues.

3. Fuel Management: Proper fuel management, including regular testing, storage in clean and secure containers, and monitoring fuel levels, is essential for ensuring the availability of fuel when needed and preventing fuel-related issues.

4. Training and Documentation: Providing training for operators and maintenance personnel on the proper operation and maintenance of the diesel generator promotes safe and efficient use of the equipment. Keeping detailed documentation of maintenance activities and performance data aids in troubleshooting and planning for future maintenance needs.

5. Emergency Preparedness: Developing an emergency response plan for power outages and system failures ensures a swift and coordinated response to minimize downtime and disruptions to the resistive loads. Regular testing of backup systems and procedures is essential for readiness.

Conclusion

Diesel generators are a reliable and efficient power generation solution for resistive loads, offering robust performance and durability in a wide range of applications. By understanding the key considerations and best practices outlined in this article, users can maximize the efficiency and reliability of diesel generators when powering resistive loads. Proper sizing, load balancing, voltage regulation, fuel management, and maintenance are essential factors to consider for optimizing diesel generator performance. By following these guidelines, users can ensure a consistent and dependable power supply for resistive loads, contributing to overall system reliability and operational efficiency.